A best-in-class electrophotographic CMYK+W system is used to print your design onto a carrier material. An infinitely long transfer medium with a maximum width of 500 mm can be printed with your design in a pin-sharp photorealistic resolution of 1200 dpi. TIGITAL® Tattoo offers incomparable chemical and mechanical resistance and an abundance of colors.

Commercially available heat transfer machines are used to transfer any printed image to the object of your choice via a carrier material by using heat and pressure. These machines, semi or fully automatic, are equipped with an eye mark reader to ensure that the image is correctly positioned on the object.

The final step in the process is then to cure the Tattoo-transferred image on the object. TIGITAL® Tattoo decorations can be cured using either convection, infrared (IR) or even near-infrared (NIR) systems, depending on the type of product and conditions.

Printing & Curing Process

Advantages of TIGITAL® Tattoo

Scratch resistance

Acids and isopropanol stability

Combination of technologies

1200 dpi quality

No stock

Total designs flexibility

Low investment

CO2 reduction, solvent free

Patents pending

All in one run: hot stamping technology

Easy to use

YOUR FIRST TIGITAL® TATTOO?

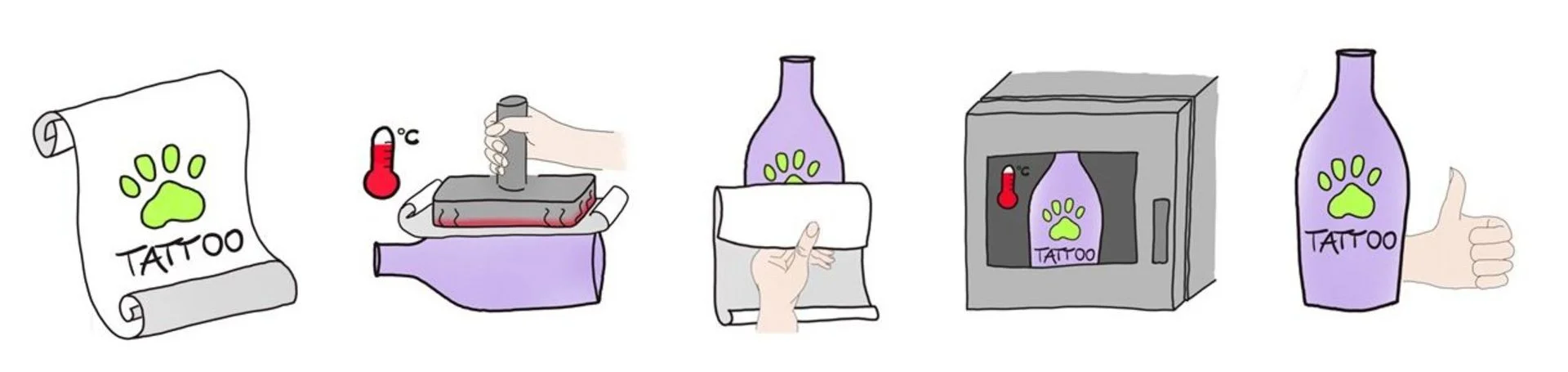

Send us your digital design.

We will check your digital motif and send you the price for your desired quantity.

We will print your design on a transfer foil and then simply send you the printed foil.

You can then transfer the design to your desired object and cure it in an oven.