Quick Links

Introduction to Powder Coating for Designers

What is powder coating?

Powder coating is a type of surface finishing that involves the application of electrostatically charged powder onto an object, commonly referred to as a substrate.

Once coating is applied, the part gets cured at a certain time/temperature making the coating go from a powder state to a hardened protective layer.

What is powder coatings made of?

Powder coatings are a unique blend of four main components - resins, hardeners, pigments and additives.

Mechanical & Chemical properties

Curing agent

Provides appearance & hiding

All the extra flare

How is powder coating applied?

Two primary methods are predominantly used across the industry - electrostatic deposition (ESD) and fluidized bed powder coating.

ESD is the more common method, especially for coating metal parts, so for the purposes of this guide, we will only cover this application technology. In this process, a spray gun applies the powder, creating an electrostatic charge that draws the particles to the grounded surface. This attraction results in a uniform and efficient coating.

It's crucial to keep dust and dirt out during this step to ensure a smooth finish. The spray gun generates a charged cloud of powder, causing the particles to adhere electrostatically to the piece, forming a consistent layer.

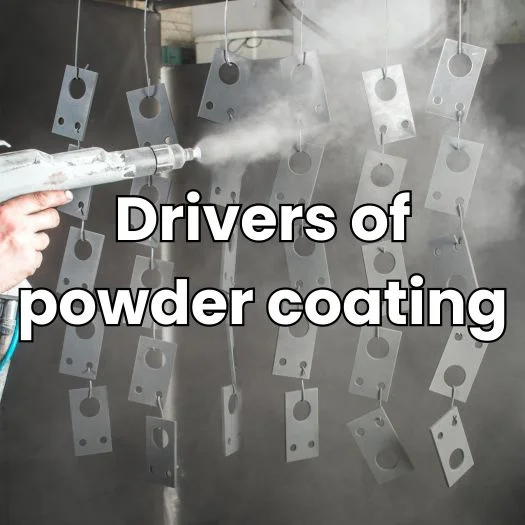

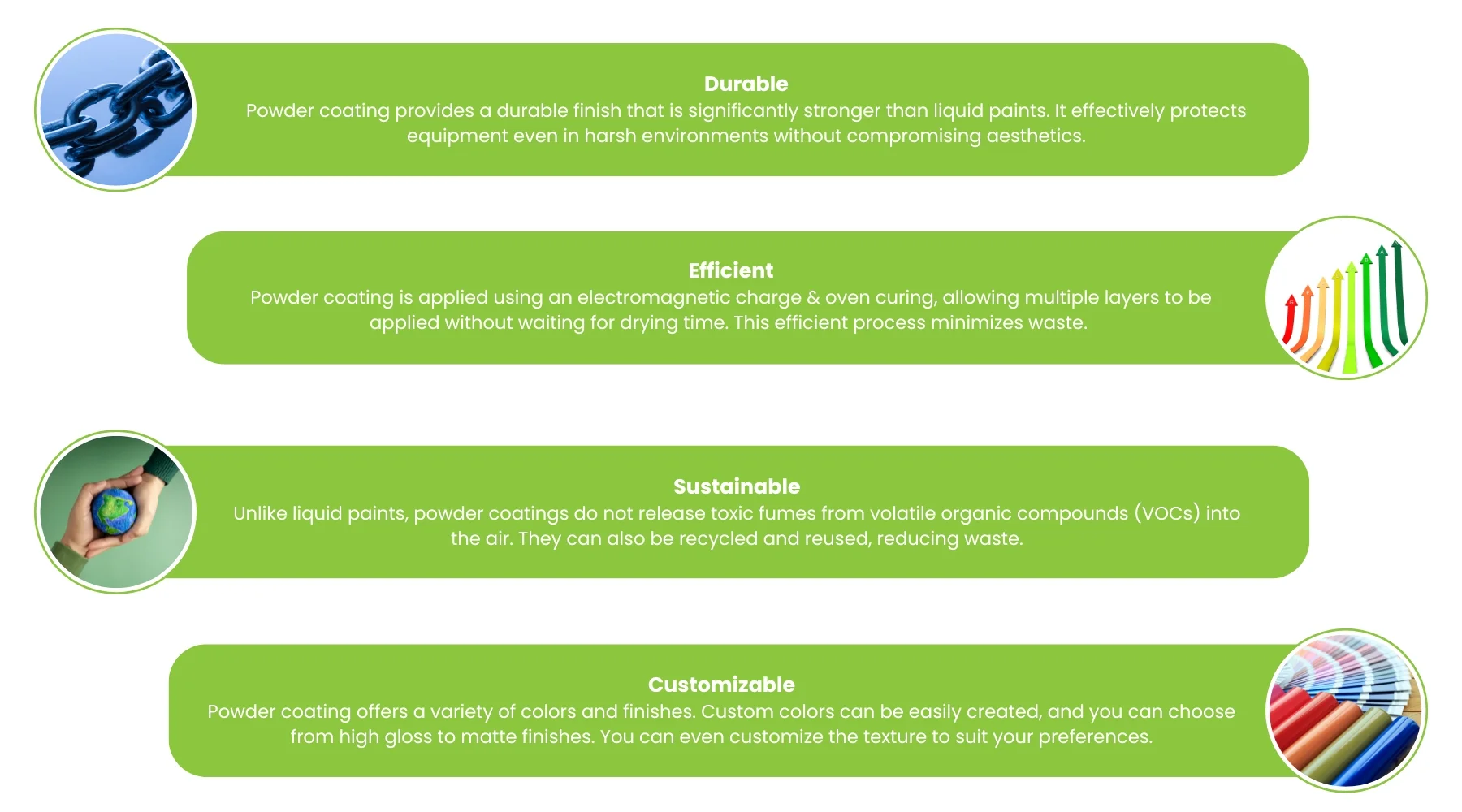

Key Drivers of Powder Coatings

Why you should consider powder coatings over liquid paint

Economic Considerations

Powder coating boasts an average material efficiency of 95%, with the added benefit of reclaiming over spray, resulting in significantly lower costs compared to liquid coating. Liquid coating in comparison, has an average material efficiency of only 35%, suffers from 50% film losses due to solvent evaporation, and cannot be recovered when over sprayed.

Environmental Considerations

Powder coatings are solvent-free, produce no hazardous waste according to RCRA*, and allow for reclaiming over spray. In contrast, liquid coatings contain solvents, emit VOCs during curing, and require hazardous waste handling for overs pray.

Mechanical Considerations

Powder coating achieves a thickness of 2-4 mils per application, offering optimal results, excellent mechanical properties due to the crosslinking process, and superior edge coverage, reducing touch-up costs. Liquid coating, on the other hand, produces only 1.2 mils of thickness per coat, necessitating multiple coats to achieve the desired thickness, and suffers from inferior mechanical properties and poor edge coverage.

Where is powder coating typically applied?

Powder coating is a versatile and widely used finishing process applied in various exterior and interior applications.

Exterior applications

- For exterior uses, it is commonly seen on building facades, curtain walls, light poles, and fixtures, as well as railings, fencing, and playground equipment.

- It's also popular for lawn and garden equipment, decorative items, patio furniture, road signs, guard rails, and posts.

- In the automotive industry, powder coating is used for racks, windshield wipers, bumpers, and mirror casings, while stadium seating and military equipment also benefit from its durability and protective qualities.

Interior applications

- Office and residential furniture, filing cabinets, light fixtures, and lamp bases are often powder coated for a sleek, durable finish.

- Home and art decor, tables, chairs, vents, registers, and ceiling fans also receive this treatment.

- Domestic appliances, electronics, and electrical enclosures are commonly powder coated to ensure longevity and resistance to wear.

- Additionally, shelving and point-of-purchase fixtures benefit from the robust and attractive finish that powder coating provides.

Ready to apply powder coatings into your design project?

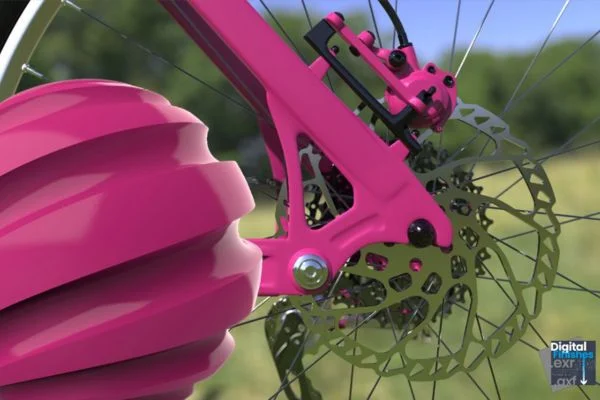

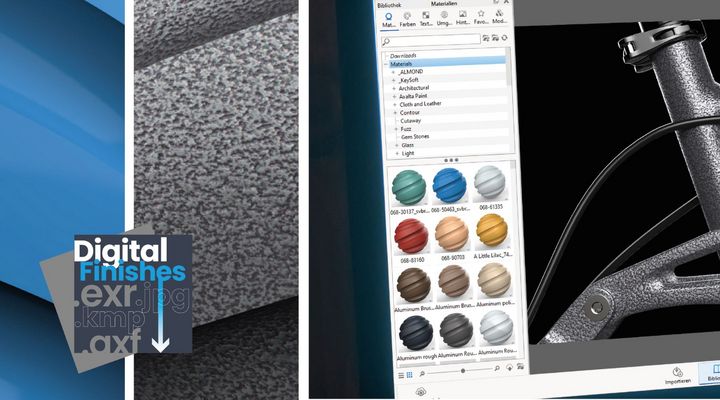

Meet TIGER Digital Finishes (TDFs) - The ultimate digital finishing solution for creating realistic digital prototypes and photo-realistic product renderings with ease.

Your challenge:

Designers and marketers face the need for accurate renderings that showcase color, gloss, and texture. Traditional photography and physical prototypes can be costly, time-consuming, and often delay time-to-market. You need a better way to visualize your products—fast, accurate, and cost-efficient.

The Solution:

TIGER Digital Finishes offer an innovative, digital-first approach to product visualization. Based on real scans of actual powder coatings, our digital finishes allow you to apply realistic textures, gloss, and effects directly to your digital prototypes and 3D renders. This gives you the power to create photo-realistic product visuals for marketing, packaging, and advertising before physical products are even made.

With TIGER Digital Finishes, you can:

- Speed up the design and prototyping process: No need to wait for physical prototypes—create digital representations of your products that look and feel real.

- Save costs on traditional photography: Avoid the expensive and time-consuming process of product photoshoots. Use TIGER finishes on your product renders to generate accurate, high-quality product images for marketing and advertisements without ever needing a physical product.

- Achieve realistic textures and finishes: Whether you’re working on 3D prototypes, product renders, or digital photography, our finishes ensure your designs are finished with authentic color, gloss, and texture.

TIGER Digital Finishes are available in more than 600 variations based on real-world scans, so you can quickly incorporate hyper-realistic digital powder coatings into your designs and visualizations. Whether you’re creating digital prototypes or digital photography for product marketing, our finishes provide a quick, easy, and scalable solution.

How It Works:

Simply download the TIGER Digital Finishes files from our free webshop. These color and effect files are available in popular formats such as .axf, .kmp, and .exr, making it easy to integrate them into your preferred rendering software.

Downloading TDFs is as simple as it can get - start using them in your design renderings or get powder coated sample panels for free today!

More than 600 TIGER Digital Finishes based on real scans in the following file formats are available for free download at free of charge from the TIGER Webshop at www.tiger-coatings.com/shop.

Our digital files work seamlessly and are compatible with popular rendering software such as:

Why Choose TIGER Digital Finishes for Your Digital Prototypes and Photography?

- Cost-effective: Avoid the high costs of traditional photography and prototype manufacturing.

- Realistic and Photo-Ready: Generate product images that are as realistic as actual photography, with precise textures, gloss, and effects.

- Fast and Efficient: Skip the lengthy product development and photoshoot schedules—create photo-realistic visualizations and prototypes in minutes.

- Sustainable: Eliminate the need for physical prototypes and the waste associated with them, all while ensuring your final product matches your digital designs perfectly.

Start Using TIGER Digital Finishes Today - Download TDFs for Free

Ready to experience the power of realistic digital finishes for your 3D prototypes and digital photography? Visit our webshop to explore over 600 digital finishes that can be applied directly to your designs. Get started today and bring your digital products to life faster, cheaper, and more accurately than ever before.

The possibilities are truly endless with TIGER Digital Finishes!

We are not only about powder coatings - Discover our other offerings for designers

High-quality digital ink solutions with TIGITAL® Inks

TIGITAL® Inks allows architects and designers to break free from conventional designs. Whether it’s facades, furniture, or other surfaces, these specialized digital inks empower you to create custom decorations that stand out.

TIGITAL® Inks meet the highest standards for durability. They can withstand harsh outdoor conditions, including rain and UV exposure, without fading or losing vibrancy over time.