Milestones on the road to sustainability

TIGER's path towards a future worth living is lined with striking milestones in the product range and a resource-conserving approach to energy and materials. Our company has been working on balancing its material and energy flows since the mid-1990s. This transparency has been the basis for our strategic "green" goals and measures for more than 90 years now.

We are expanding our PV capacity by 375 kWp and now have a total of 925 kWp installed at our site in Wels.

TIGER participated in the “Alles Radlbar” campaign organized by the Wels Umland model cycling region and won a prize for having the most participants. Over the summer, more than 8,500 km were covered by bike.

TIGER extends its Climate Alliance membership for another 8 years and is part of Austria's largest municipal climate protection network.

Picture: © Cityfoto / Roberta Pelzl-Mairwöger

TIGER is aware that in order to master the challenges of our fast-moving and complex times, companies need diverse leadership energy in an inclusive working environment in which everyone is valued and accepted as a valuable individual. The first TIGER Diversity Talk was organized to give this topic more space.

In 15-minute workshops, small groups discussed the importance of CO2 and the amount of CO2 emissions bound in our products in more detail. In addition, topics were defined for follow-up workshops, which take place at regular intervals in all areas.

Nearly 70 TIGER employees took the opportunity to gain exciting insights into our sustainability initiatives at the Green TIGER World Café! In areas such as Production, People & Culture, Sales & Marketing, IMS, R&D, and SCM, our experts shared the diverse measures TIGER is taking to create a more sustainable future.

A big thank you to all the speakers for their commitment and to the participants for the lively discussions!

TIGER Austria participates in the Responsible Care program. Responsible Care is a worldwide, voluntary initiative of the chemical industry, which has imposed strict self-controls for the purpose of improving the health, safety and environmental situation. By participating, TIGER demonstrates that we consider safety and the protection of people and the environment in products, processes and plants to be a top priority.

TIGER installs a comprehensive solar energy system at our St. Charles production facility, utilizing both rooftop and ground-mounted solar panels on our unused land. The system boasts a capacity of 951.23 kW-DC, comprising 1,778 solar panels and 31 inverters.

TIGER's apprentices are climate checkers@work. As part of the "NachhalTigAir" project, they detect leaks in the compressed air network and thus help to minimize unnecessarily wasted resources.

Our photovoltaic system at the Wels site is extended by 180 kWp.

The TIGER Energy Officers start their work: 15 committed employees work together to implement effective sustainability projects.

Based on the Sustainable Development Goals, TIGER defines seven global sustainability ambitions that we want to achieve by 2030.

TIGER integrates the United Nations’ Sustainable Development Goals (SDG) into his corporate strategy and goals.

We are launching the GREEN TIGER Award and honoring sustainable ideas from our employees at the big TIGER annual celebration.

TIGERs next step away from fossil fuels: We connect our buildings in Wels to district heating.

Charge up and drive off!

We set up the first charging stations for e-cars on the factory premises in Wels.

As a pioneer, TIGER has been working on its material and energy indicators since the early 1990s. In 2020, we drew up a comprehensive material and energy analysis for all regions.

At the ultra-modern TIGER R&D Center, sustainability has been an integral part of all development activities for years. Find out more about our current research priorities.

Our 370 kWp photovoltaic system goes into operation.

The power generated by the 1,914 m2 system on the roofs of the factory buildings covers around two percent of TIGER's total electricity needs at the Wels site.

The Gemba Support Center (GSC) is officially opened during the “Long Night of Research”. This modern office building is heated by a heat pump which uses a cooling basin from production as a heat source.

Estimated savings:

125,000 kWh/a (heating)

135,000 kWh/a (cooling)

In November 2018 TIGER receives the Energy Star of the Province of Upper Austria. Our GSC took first place in the "Energy Innovation for Sustainable Workplaces" category.

TIGER joins Climate Alliance Austria, a global partnership between European municipalities, businesses and educational institutions to protect the global climate and support indigenous peoples in the Amazon rainforest regions.

Beat the heat!

TIGER starts producing “Cool Roof” powder coatings for facade applications.

In the same year, we also install an online energy monitoring system at the Wels site.

Compressed air leaks mean energy loss, and energy loss means rising costs. This is why TIGER checks its compressed air lines annually since 2011 and has them repaired on the spot.

TIGER says goodbye to conventional boilers and replaces them with energy-efficient condensing technology.

TIGER starts replacing old light fixtures with LED light. Today, more than 70 percent of our lighting consists of LED light sources.

An intelligent lighting system is installed on the roof of our R&D center. A sensitive sensor system measures daylight and automatically controls the amount of light needed in the work areas. This saves energy and ensures ideal lighting conditions.

We are constructing an energy-efficient cooling water well for cooling buildings and production processes. Up to 400 m3/h of 12 °C cold groundwater can be extracted from the well and fed back into the ground at a maximum of 20 °C after the cooling process. A separate measuring point ensures that the groundwater is not affected by this process.

TIGER is starting to use heat from manufacturing processes as often and as efficiently as possible. Heat recovery systems and heat exchangers ensure that the waste heat from our production is reused several times instead of simply being blown into the air.

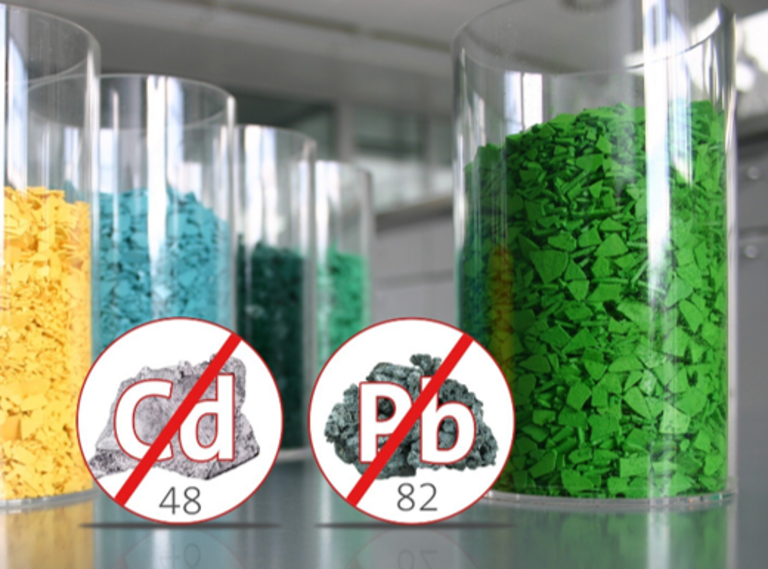

Goodbye heavy metals!

TIGER is one of the first companies in the German-speaking world to dispense with lead and cadmium pigments in the production of powder coatings for interior use.

Kurt Berghofer ventures into the then still largely unknown, revolutionary powder coating technology and anchors the green idea in the TIGER organization.