With FlexCURE Series 45, TIGER is redefining the industrial standard for modern surface finishing. Developed for maximum flexibility, highest efficiency, and improved environmental compatibility, this innovative product line offers an exceptionally wide curing window – ideal for demanding industrial applications.

Why FlexCURE?

TIGER´s FlexCURE technology delivers exceptional flexibility and impressive energy efficiency. TIGER Drylac® Series 45 FlexCURE has been rigorously tested and meets the high quality standards of the established Series 59.

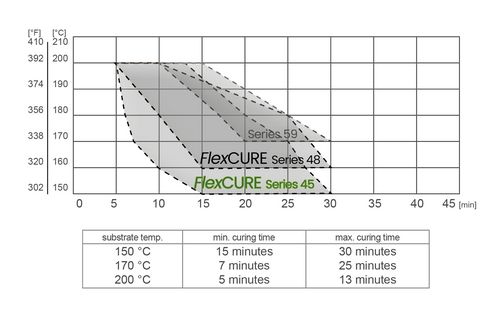

The core of Series 45 is its expanded curing window from 302 °F to 392 °F (150 °C to 200 °C).

Your Benefits at a Glance

Flexible curing parameters: Curing between 150 °C/15 min – 200 °C/5 min object temperature – perfect for components with varying material thicknesses.

Energy-efficient production: Reduced curing temperatures lower energy consumption and CO₂ emissions.

Process reliability & efficiency: One product for different component types – no oven adjustments required.

Compatible with Series 59 & Series 48: Easy system changeover without temperature adjustment.

Durable and robust surface: High resistance to mechanical, chemical and weather-related impacts.

Versatile Applications – Indoors and Outdoors

Whether for functional industrial parts or demanding design solutions, FlexCURE Series 45 delivers reliable results across a wide range of applications

Special Features (on request):

- ESD (Electrostatic discharge detection)

- Abrasion-resistant

- OGF (outgassing-foregiving)

- Thin-film (40–60 µm)

- PFAS n.i.a. (not intentionally added)*

*Available for smooth surfaces on request

Experience the next generation of powder coatings. Contact our team for more information or color samples.