With FlexCURE Series 45, TIGER is redefining the industrial standard for modern surface finishing. Developed for maximum flexibility, highest efficiency, and improved environmental compatibility, this innovative product line offers an exceptionally wide curing window – ideal for demanding industrial applications.

Why FlexCURE?

TIGER´s FlexCURE technology delivers exceptional flexibility and impressive energy efficiency. TIGER Drylac® Series 45 FlexCURE has been rigorously tested and meets the high quality standards of the established Series 59.

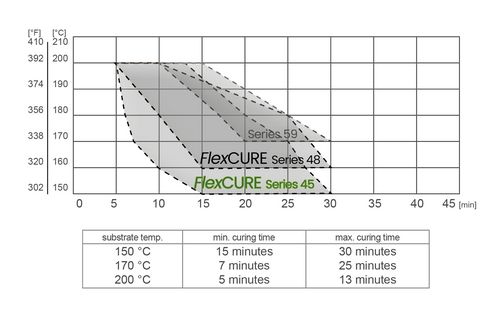

The core of Series 45 is its expanded curing window from 302 °F to 392 °F (150 °C to 200 °C).

Product Highlights

Your Benefits at a Glance

Flexible curing parameters: Curing between 150 °C/15 min – 200 °C/5 min object temperature – perfect for components with varying material thicknesses.

Energy-efficient production: Reduced curing temperatures lower energy consumption and CO₂ emissions.

Process reliability & efficiency: One product for different component types – no oven adjustments required.

Compatible with Series 59 & Series 48: Easy system changeover without temperature adjustment.

Durable and robust surface: High resistance to mechanical, chemical and weather-related impacts.

Versatile Applications – Indoors and Outdoors

Whether for functional industrial parts or demanding design solutions, FlexCURE Series 45 delivers reliable results across a wide range of applications

- Machine and equipment components

- Enclosures for electronics and control systems

- Steel and aluminum components

- Storage and transport containers

- Workshop furniture & workplace equipment

- Frame and support structures

- Radiators & technical components

- Indoor & outdoor furniture, garden furniture

- Fences, gates and garden elements

- Shopfitting systems

- Refrigeration units, sports equipment, shelving systems

Technology Highlights

Extended curing window

FlexCURE technology enables safe, energy-optimized curing between 150–200 °C. This makes Series 45 ideal for components with complex geometries or high thermal mass.

Process compatibility without adjustments

Thanks to overlapping curing parameters, Series 45 is fully compatible with TIGER Drylac® Series 59 and 48. Switching between coating systems is possible without any modification to oven settings.

Sustainability that pays off

Lower curing temperatures mean reduced energy usage – lowering operating costs and decreasing the ecological footprint.

Flexibility You Can Count On

FlexCURE Series 45 combines peak technical performance with economic efficiency and more sustainable production – delivering long-lasting coatings and versatile design options. Whether for heavy-duty structures or delicate elements, FlexCURE is always the right choice.

Special Features (on request):

- ESD (Electrostatic discharge)

- Abrasion-resistant

- OGF (outgassing-foregiving)

- Thin-film (40–60 µm)

- PFAS n.i.a. (not intentionally added)*

*Available for smooth surfaces on request

Experience the next generation of powder coatings. Contact our team for more information or color samples.

Note: The used images were created with support of artificial intelligence.