Powder Coating on Plastic

A very common question in powder coating is whether you can coat certain substrates or not. Of course, metal applications like aluminum and steel are the most common, but that does not mean, that it is not possible to work with other types of materials. For instance, wood, glass, ceramics and even certain plastics can be powder coated. There are however a few things to look out for!

Which plastics can be powder coated?

Basically, every type of plastic can be powder coated, given that they withstand temperatures of at least 130 °C. That includes materials such as glass, carbon fiber reinforced materials, polyamides and our own TIGITAL® thermoset material for 3D-SLS printing. When powder coating plastic parts however, applicators must take care of limitations due to the insulating behavior of plastics, as they are not conductive like metal substrates, influencing the powder deposition on the part. That’s why in these cases a hot coat application or a conductive pretreatment, like TIGER Static Fluid, is being used.

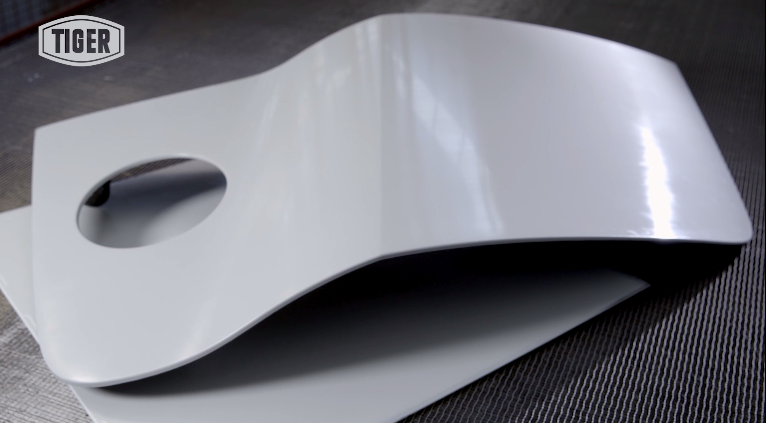

Powder In-Mould Coating

Composites are the materials of the future offering excellent mechanical and structural features. They are used in a wide range of high-performance applications in industries such as aerospace, automotive, transportation and renewable energy. TIGER offers solutions for the refinement of fiber-reinforced plastics, to provide surfaces of the highest quality with an attractive look and feel. These solutions include primers as well as topcoats. During powder-in-mold coating, highly reactive powder coating is applied to a preheated press mold, where it immediately begins to gel. This is followed by the fiber-reinforced plastic material, which can be demolded after pressing as a finished coated component. This one-step process is compatible with all common release agents and enables resistant surfaces in Class A quality. So-called telegraphing (fiber printthrough), which can occur on conventionally coated fiber composites due to the influence of temperature or moisture fluctuations, is effectively prevented by TIGER’s PIMC process.

Powder-in-mold coating can be combined with all common technologies for manufacturing fiber-reinforced plastics, with nearly all thermoplastic and thermoset FRP matrix materials, and with all fiber types and geometries. Even composites with components made from sustainable raw materials - so-called "bio composites" - are compatible with the process.

To learn more, contact our PIMC-Team: pimc(at)tiger-coatings.com

Where are they used?

Powder coating on plastics and PIMC can be used in several areas of everyday life. Below you can find some examples:

- Structural and decorative parts for…

- Automotive applications

- Aerospace construction

- Railway industry

- Components for…

- Sports & Leisure (bike frames, attachments …)

- Electronical applications

- Nautical equipment

- Wind turbines

- Solar energy

- Prostheses

- And many more

Want to discover all possible applications?

Then reach out to us: pop(at)tiger-coatings.com

TIGER Solutions

With over 1600 stock products, browse through our webshop to find the right powder for your plastic coating application. However, we especially recommend our low-cure series powders for such applications. In case of carbon fiber parts we have also developed a special clear coat solution for the automotive sector!

Not sure which one fits your product best? – No problem! With our state-of-the-art R&D-Center we can test different coatings with your own parts to find the optimal solution for you case!