FAQ’s FlexCURE Series 18 matte

Yes, you have full flexibility within the curing window to decide which settings to use in your production. TIGER has carefully considered customer needs and designed the new curing window to overlap significantly with the previous one. By way of illustration, if you have been curing your parts at 200°C for 10 minutes and prefer not to change this setting, you can continue to do so.

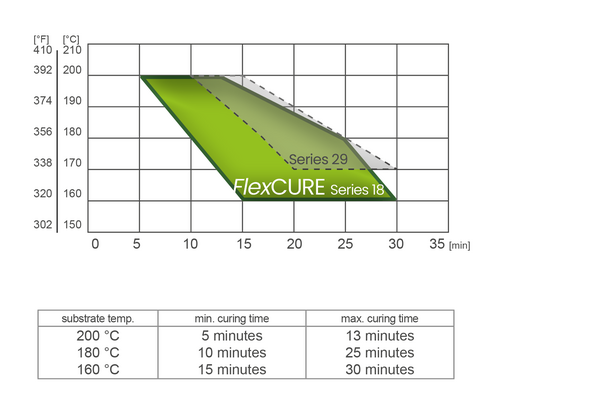

The following graphic illustrates the extended curing window of Series 18 matte in comparison to previous curing conditions:

For the FlexCURE technology, synthetic resins have been further developed or newly formulated. This allows the curing window to be extended to temperatures ranging from 160 to 200 °C, offering maximum flexibility in selecting curing conditions.

Both the visual and functional properties, as well as the weathering resistance of the products, meet the standards of relevant quality associations.

The colors of the FlexCURE Series are matched to the existing TIGER Drylac® Series. Therefore, usual batch-to-batch variations can be expected.

Yes, as before, there are the usual variations in color and gloss within the curing window.

Laboratory tests have shown that the new FlexCURE Series 18 matte is technically compatible with the previous Series 29 matte. Mixing the two does not result in incompatibility. However, line specific factors may lead to different results.

Therefore, we recommend cleaning the system when switching products, just as with any color change.

The compatibility with other powder coatings from different manufacturers remains unchanged with this transition. However, it is important to continue the usual cleaning procedures for the line equipment.

Yes, FlexCURE Series 18 matte is certified with GSB Florida 1 (174 q) and QUALICOAT Class 1 (P-2172).

The EPD certificate for FlexCURE Series 18 can be found here.

Starting June 26, 2025, FlexCURE Series 18 smooth matte will replace the previous Series 29 smooth matt product line.

As a first step, starting June 26, 2025, 30 selected products from the current Series 29 matte will also be available from stock in FlexCURE Series 18 matte.

All other standard RAL colors and metallic effects from Series 29 matte will follow gradually as part of a controlled phase- out/phase-in process.

Series 29 matte will only be available while supplies last and will be replaced by Series 18 matte with each new production. When you place an order, we will inform you accordingly and automatically supply the new FlexCURE Series 18 matte variant.

In addition, we provide a landing page where we continuously update which products are already available in Series 18 matte. We recommend bookmarking this landing page to ensure you order the appropriate Series 18 matte product for new purchases and to avoid order corrections. If needed and upon request, products from Series 29 matte can still be ordered as custom-made items.

The 5-digit product number after the series designation will (with few exceptions) remain unchanged; only the series number will change. For example: RAL 7016 matte 29/73570 becomes RAL 7016 matte 18/73570. The overview provides all product numbers for the entire Series 18 matte FlexCURE, enabling you to update the material master data in your ERP system accordingly.

Construction projects are often coated over extended periods and may even require followup coatings at a later point in time. During the transition phase, we cannot guarantee the availability of specific series and batches at a later time. Therefore, we recommend coating projects directly with FlexCURE with unchanged curing settings whenever possible.

If necessary, the previously used TIGER Drylac® product can still be obtained as a custom order product. The processing guidelines and the recommendation to use the same batch for a project whenever possible remain unchanged with FlexCURE.

Version 06_2025