Resource-Efficient Powder Coating: 5 Tips for Coating Operators

Sustainability has gained an increasing amount of relevance. As the topic becomes more important, manufacturers as well as powder coaters are required to think of novel ways to design their production and processes. This article gives you five tips with which you can make your coating process more efficient!

1. Pay attention to low curing temperatures

Reducing the curing temperature, according to the recommendations in our Technical Data Sheet, not only reduces energy consumption, but also the amount of CO2 emitted can be significantly decreased. To counteract the occurrence of gradients, our low-cure powder coatings are recommended.

2. Use lower coating thickness

A reduced coating thickness has a direct positive impact on the sustainability of the coating process. On the one hand, material consumption is significantly reduced, and on the other hand, the amount of energy required can also be reduced as a result. The recommended film thickness for powder coatings does rarely exceed 80µm.

But beware: especially low coating thickness can affect the opacity of powder coatings - a problem that can be solved by higher pigmentation.

3. Opt for weathering stability.

Many people know that powder coatings have a higher weathering stability compared to other alternatives. However, this effect can be further exploited by using particularly resistant powder coatings. TIGER offers different powders in categories ranging from durable to hyper durable. Current systems are based on fluoropolymers. These powder coatings achieved top results in the GSB Florida test over 10 years.

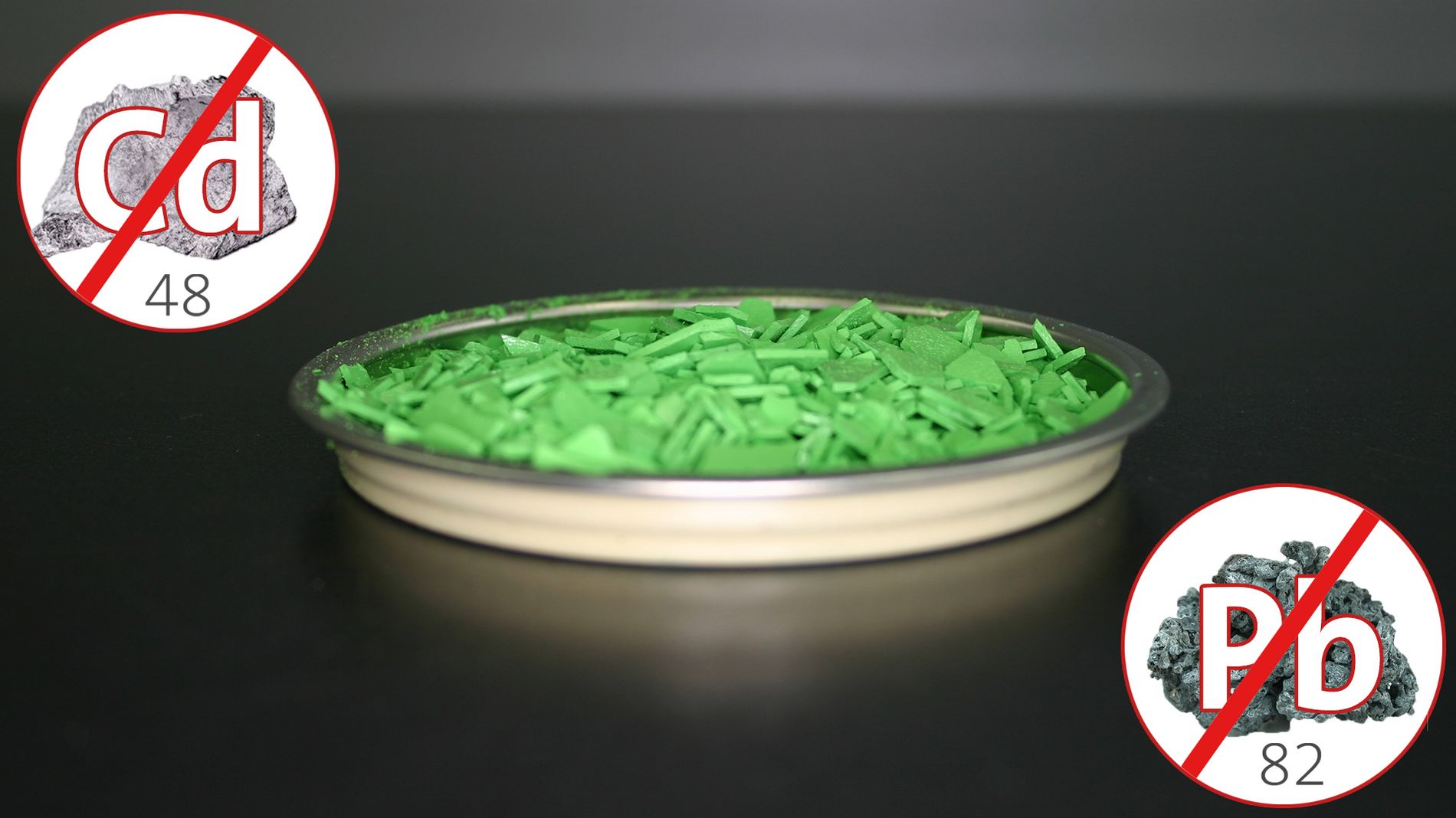

4. Avoid toxic/environmentally harmful substances

Most powder coatings not only avoid solvents. Depending on the manufacturer they also do not contain heavy metals of all kinds or any other toxic and environmentally harmful substance. At TIGER we are proud to be heavy-metal free since over 30 years!

5. Reduce use of fossil fuels

If infrastructure and costs allow, we advise coaters to use bio-based raw materials. An increased share of renewable energy can also make a significant contribution to the sustainability of one's own operations. This applies not only to the coating plants themselves, but also to the entire production site.

Low cure:

- TIGER Drylac ® Series 418 interior and exterior applications

- TIGER Drylac ® Series 40

Low Cure Primer:

Weathering stability:

durable:

super durable:

- TIGER Drylac ® Series 56

- TIGER Drylac ®Series 68

hyper durable:

- TIGER Drylac ® Series 75

Back to overview