TIGER Digital Finishes - An Industrial Designers View

In the dynamic world of CMF and industrial design, efficient decision-making and creative freedom are crucial to the success of a project. TIGER Digital Finishes (TDF) offer a pioneering solution for the digital visualization of surfaces that not only saves time and resources but also increases the quality of the design process. In total designers can choose between 1,500 digital finishes in the file formats .axf, .kmp, .exr and more, all available for free download on our Webshop. We had the opportunity to talk to Bernhard Kaliauer, Industrial Designer and Owner of Studio KID, about how he is utilizing these files and the importance of TDFs for his projects.

Info - Studio KID

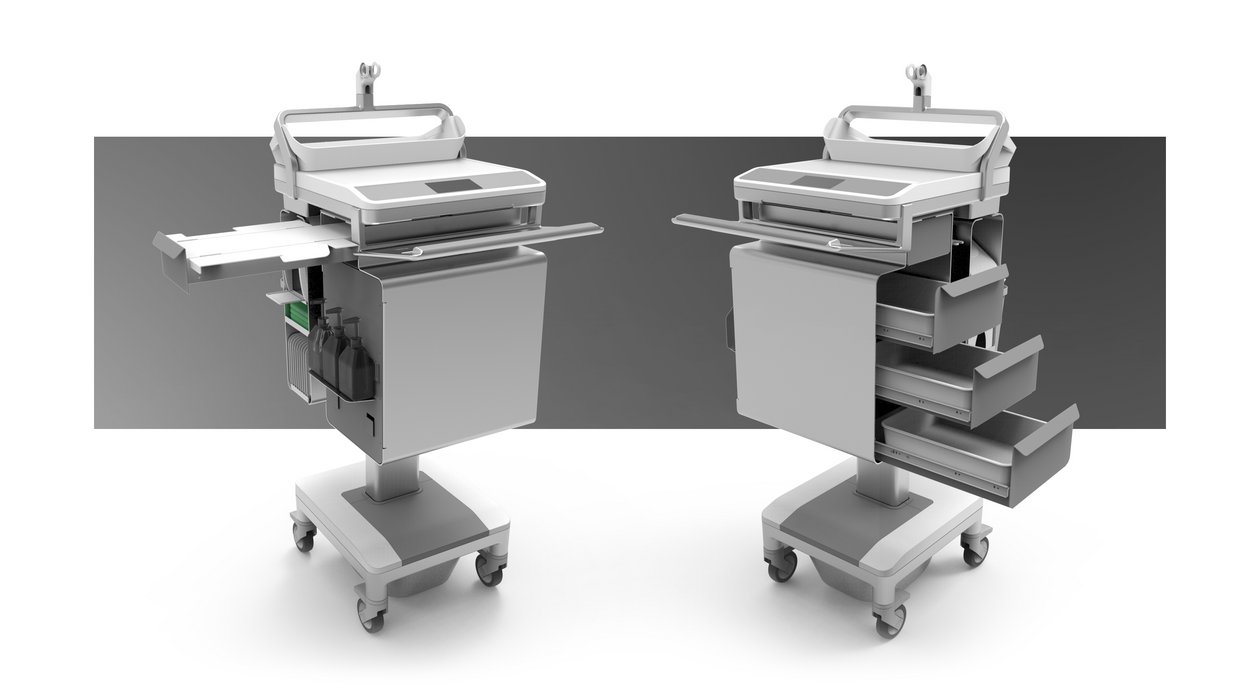

The Austrian Studio KID, founded by Bernhard Kaliauer, stands for sustainable product design that impresses with its precision and efficiency. Using state-of-the-art CAD modeling, high-quality prototyping and a deep understanding of design and manufacturing processes, the Linz-based design studio develops innovative product solutions that strengthen brands and improve the user experience.

TIGER: To what extent does powder coating play a role in your industry?

Bernhard Kaliauer: Powder coating plays an extremely important role in my field of work. I work closely with companies in the transportation and sheet metal processing industries, where high demands are placed on surface quality and durability. In these areas, liquid coatings often cannot provide the same level of durability as powder coatings. In fact, powder coating has become almost an indispensable coating technology for metal products. Other types of coatings are only considered when specific requirements call for them. Particularly in large companies, powder coating is already a standard, to smaller fabricators we actively recommend this technology. As a designer, it is essential for me to stay ahead of the curve. Powder coating gives us creative freedom, which I can pass on to my clients directly. My goal is to provide my customers with the best possible solution so they can express their expertise and innovation through design.

TIGER: On which objects do you plan powder-coated surfaces? And what do you see as the advantages of this coating technology?

Bernhard Kaliauer: We primarily use powder coatings when working with industrial sheet metal applications — where high surface quality and durability are required. Another major advantage of powder coating is its ability to cover even intricate geometries seamlessly. This makes it ideal for machine housings, motorcycle frames, or heavy machinery like excavators. Things become especially interesting when different materials come together — for example, an injection-molded plastic fender, anodized parts, and a powder-coated frame. It is crucial that all colors are perfectly matched. Powder coating significantly contributes to achieving a uniform and high-quality color design.

TIGER: When do you use TIGER Digital Finishes?

Bernhard Kaliauer: Whenever possible. Renderings are an essential part of every project. TDFs play a crucial role not only in communication between designers and manufacturers but also for the end customers. For example, product catalogs can be prepared even before the product goes into mass production. One major advantage is the precise coordination and correction of surfaces. Whether glossy, matte, or fine-textured—the TDFs provide a representation that is 99% true to the final product. It is, of course, important that our monitors are perfectly calibrated. I regularly check and calibrate my screens to ensure absolutely realistic color reproduction. Especially with shades like gray, there are countless variations that must match the final product exactly. With TIGER, I can trust that the digital finish and the actual result are identical—and that is invaluable for my work. I don’t know of any other paint manufacturer that offers A comparable quality.

TIGER: Since when have you been familiar with TIGER Coatings?

Bernhard Kaliauer: I have known TIGER Coatings since my youth — certainly during my carpentry apprenticeship, when I first encountered the company’s products. The DIY coatings were already well known to me back then. Today, I have been working intensively with TIGER for several years, particularly through the TIGER Digital Finishes (TDFs). My contact with them developed through designer workshops, and for about two years now, I have been working closely with TIGER’s digital materials.

TIGER: At what stage in the design process do TDFs come into play?

Bernhard Kaliauer: My studio sees itself as a full-service agency that accompanies the entire design process, from the first idea to the finished CAD file. Renderings already play an important role in the early research phase, especially in defining the color scheme of a new product. This means that TDFs often come into play even before the actual design phase. Color influences the design from the very beginning. By the end of the design phase, the renderings must match the final color exactly.

TIGER: Which software do you use for TDFs? And how did you previously "coat" your designs on the PC?

Bernhard Kaliauer: We primarily use KeyShot because it allows us to quickly and efficiently create high-quality visualizations. In recent years, however, we have increasingly turned to Blender, especially for highly realistic renderings. Blender is becoming more established in the design process as it offers high quality and enables quick adjustments. Previously, without digital material files, we had to painstakingly recreate surface materials in the respective software—a highly complex and time-consuming process.

TIGER: Would you recommend TDFs? And if so, to whom?

Bernhard Kaliauer: Absolutely—100%! I recommend TDFs to anyone working with colors who needs realistic visualizations of their designs. They are an incredibly valuable and supportive tool in my workflow. For designers, product developers, and manufacturers, they are worth their weight in gold!

Back to overview