Effective Corrosion Protection with Powder Coatings and Primers

Where there is metal, there is a potential for rust! If such damage is not detected in time, it can lead to material failure. In industrialized countries, the annual loss due to corrosion can amount to about three to four percent of the gross domestic product. Based on the G20 countries, the global economy lost between USD 2.4 to 3.15 trillion to corrosion in 2021 alone.

Corrosion happens everywhere

High humidity, temperatures above 0 °C, and reactive air contaminants, such as sea salt, are the big drivers of metal corrosion. In addition, aggressive chemicals can trigger, favor and accelerate this process. If no countermeasures are taken, a steel surface can degrade up to 200 µm of layer thickness in just one year.

Prime correctly - Prevent corrosion

High-quality pretreatment in combination with powder coating offers good protection against weathering. However, one coat of powder is often not enough, especially for applications in conjunction with steel. For example, on sharp edges, there is only a small amount of powder coating after treatment when compared to the remaining surface. This in turn impairs the corrosion protection of the entire surface. For these applications, TIGER Drylac offers powder coating primers that are applied to the substrate before the topcoat. The special formulation of the primers and the additional coating thickness provide optimum protection against corrosion for a wide range of equipment, machinery and plants.

Important areas of application for primers

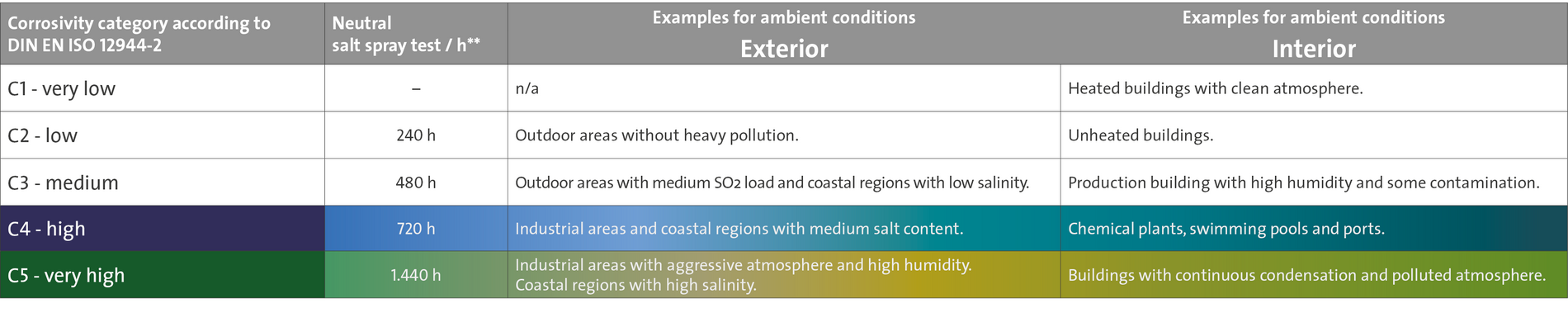

Primers are available in different colors and qualities for steel, galvanized steel and aluminum. The 2-layer system structure, consisting of powder coating primer as well as topcoat, is particularly suitable for areas of application that can be classified under the corrosivity categories C3, C4 and C5 according to DIN EN ISO 12944-2:

C3 (moderate pollution)

- Outdoor: urban and industrial atmosphere with moderate air contamination

- Indoor: production premises with high air humidity and low air contamination

C4 (heavy pollution)

- Outdoor: industrial areas and coastal regions with medium levels of salt contamination

- Indoor: chemical plants, swimming pools

C5 (very high pollution)

- Outdoor: industrial areas with high humidity and aggressive atmosphere, coastal regions and off-shore facilities with high salt contamination in the air

- Indoor: buildings with continuous condensation and polluted atmosphere

TIGER Primer Solutions

With TIGER SHIELD, TIGER has developed a system that permanently protects steel and galvanized substrates against corrosion. In addition to use on steel and galvanized steel, selected TIGER Drylac® primers can also be used for aluminum substrates.

Primer Epoxy-based powder coating for corrosion protection application up to corrosivity category C5-H according to DIN EN ISO 12944.

- Universal primer for all substrates

- Outgassing friendly

- Very good edge coverage

Primer epoxy-based low-cure powder coating for corrosion protection application up to corrosivity category C5-H according to DIN EN ISO 12944.

- Especially suitable for thick-walled steel components

- Low temperature

- Very good edge coverage

- Good mechanical properties

Epoxy-polyester based primer powder coating with excellent flow for corrosion protection application up to corrosivity category C4-H according to DIN EN ISO 12944.

- Suitable for aluminum and steel

- Outgassing friendly

- Excellent flow

- Especially suitable for overcoating with wet paint

Polyester-based primer powder coating for corrosion protection applications up to corrosivity category C5-H according to DIN EN ISO 12944, depending on the substrate, metal preparation and pre-treatment.

- Suitable for aluminum, steel and galvanized steel

- UV-stable: especially suitable for UV-permeable top coats

- Very good edge coverage

- Good mechanical properties

Back to overview