Why Particle Morphology Matters in Powder Coating: A Deep Dive into Performance, Control, and Optimization

In the world of powder coating, particle morphology is an often-overlooked factor with far-reaching impact. It’s one of those technical elements that seems minor—until you realize it underpins everything from film smoothness to spray efficiency. The shape, size, and distribution of powder particles aren’t just scientific details; they’re critical drivers of coating performance and consistency.

In this article, we explore how particle morphology shapes outcomes on the line—and how manufacturers manage these variables to ensure reliable, high-quality results.

What Is Particle Morphology in Powder Coating?

Particle morphology refers to the size, shape, and surface characteristics of individual powder coating particles. These particles are typically composed of a blend of resins, pigments, fillers, and additives that have been extruded, milled, and classified into a free-flowing powder.

Two primary aspects define powder coating particle morphology, and they are:

- Particle Size and Distribution

- Particle Shape and Sphericity

Let’s dive deeper into how these individual properties affect overall quality and performance of the produced powder coating.

Why Particle Size Matters

Particle size and its distribution (more on the distribution aspect later) affect nearly every stage of the powder coating process. An ideal size range ideally falls between 12 and 80 microns.

- Oversized particles (>80 μm) tend to drop out of the spray pattern, reducing transfer efficiency and resulting in uneven film thickness.

- On the flip side, overly fine particles (<12 μm) can absorb moisture, clog application equipment, and cause surface defects such as orange peel or mottling.

The Critical Link Between Particle Size and Powder Coating Quality

In powder coating, particle size directly influences coating performance and consistency. From film texture and gloss to fluidization, storage stability, and powder recovery, nearly every step in the process is affected by how powder particles are engineered.

Below are five key areas where particle size has a measurable impact on coating quality and process efficiency:

Appearance and Surface Smoothness

Smaller powder particles - in the lower end of the 12-to-80-micron range - tend to produce smoother finishes. Finer particles create a more uniform surface with fewer visible defects, especially when applied at the same coating thickness. Because they settle more evenly, the final cured film appears more refined, with enhanced leveling and reduced surface texture. However, if the particle size becomes too fine, it may lead to issues like poor flow or orange peel due to uneven charge or inconsistent deposition.

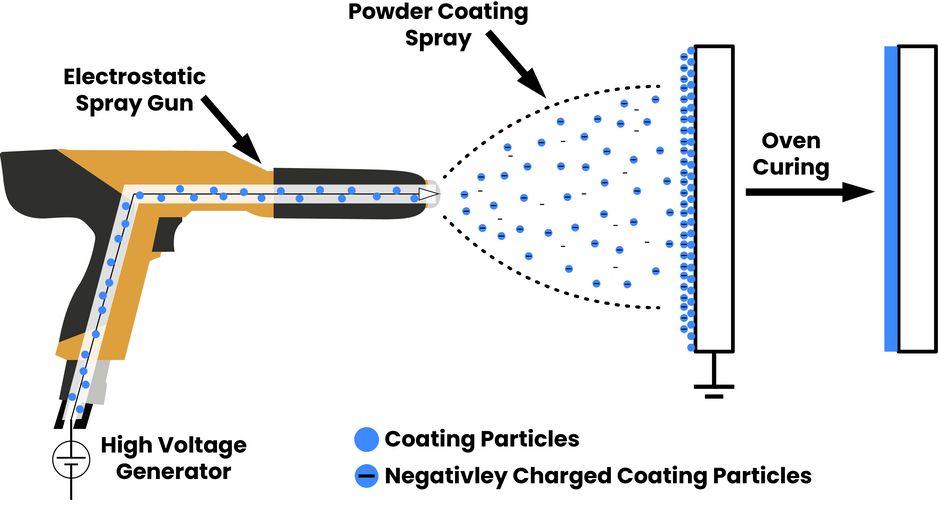

Electrostatic Efficiency and Application Rate

Powder particle size also plays a role in how well powder charges and adheres during electrostatic application. Overly fine particles often carry a weaker charge and are less likely to reach the target surface efficiently, leading to lower transfer efficiency. On the other hand, very large particles can be affected by gravity more than electrostatic or aerodynamic forces, causing them to fall out of the spray path before reaching the part — reducing overall powder utilization.

Optimal particle size strikes a balance: small enough to achieve good surface quality, but large enough to carry charge effectively and reach the surface.

Powder Flow and Fluidization

When powder particles are too fine, they tend to clump together, which interferes with proper fluidization and flow during the application process. This can result in uneven spray patterns and poor coating appearance. Conversely, excessively coarse powder doesn’t fluidize easily in hoppers, making it harder to handle automated systems.

Storage and Shelf Stability

Storage stability is another critical concern. Powder coatings must retain their particle structure and consistency over time without clumping or absorbing moisture. Ultrafine powders (especially those under 12μm) are more prone to absorbing humidity, which can lead to caking, blockages in spray guns, and poor spray quality. Maintaining an ideal particle size distribution helps ensure long-term stability and usability.

Powder Recovery Efficiency

In both production and end-use environments, powder recovery is essential for cost efficiency and sustainability. Ultrafine particles (below the ideal range) are more difficult to recover effectively, often escaping through filters or settling unevenly. As particle size increases beyond this threshold, recovery rates rise significantly — making it easier to reclaim and reuse material without sacrificing quality.

The Role of Particle Shape and Sphericity

Just as particle size and distribution, the shape of the powder particle is equally important. Spherical or high-circular particles reduce interparticle friction, improving powder flow, fluidization, and charging behavior.

Moreover, smoother shapes minimize the risk of agglomeration and ensure more uniform film formation during curing. This is because irregularly shaped particles can interlock, resist flow, and introduce inconsistencies across applications.

Here are the specific ways particle shape impacts powder performance.

- Application Flow & Fluidization

Smooth, near-spherical particles fluidize more easily in hoppers, creating consistent spray patterns and minimizing clogging. In contrast, angular or irregular particles can interlock, hampering fluidization and causing spray inconsistencies.

- Electrostatic Transfer Efficiency

Spherical powders charge more uniformly during electrostatic spraying, enhancing adhesion and reducing overspray. Irregular particles may charge unevenly or less efficiently, lowering transfer efficiency.

- Surface Appearance & Finish Smoothness

Particle shape can also influence the occurrence of surface defects like orange peel. Uniform particles melt and level more effectively during curing, producing smoother, glossier films. Inconsistent or rough particles, however, disrupt flow and encourage texture flaws.

Understanding Particle Size Distribution (PSD) and its role in Powder Coating Quality & Performance

Beyond individual particle size or shape, the overall particle size distribution (PSD) is another important factor influencing powder behavior during application and curing.

What is PSD?

PSD describes the range and proportion of particle sizes present in a powder sample—essentially mapping out how fine or coarse the overall blend is.

PSD directly influences how the powder flows, how well it reclaims during application, and how the final finish appears. For instance, larger particles tend to flow more easily than smaller ones, while a well-balanced PSD helps reduce defects like orange peel and improves overall leveling.

Because of this, PSD can be a powerful tool for both process control and troubleshooting. It can help manufacturers diagnose issues with application consistency, surface smoothness, and even the efficiency of reclaim systems.

Does PSD Affect Leveling?

Leveling refers to the coating’s ability to melt, flow, and form a smooth, uniform film during the curing process. Poor leveling can result in visual defects such as orange peel, waviness, or surface texture that detracts from the final finish.

Particle Size Distribution (PSD) does play a direct role in leveling because it influences how particles pack, melt, and flow across a substrate. Here's how:

- A narrow PSD (most particles are similar in size)—can promote more uniform melting and smoother film formation. However, it may reduce packing density, which could lead to inconsistent film build.

- A broader PSD (a mix of fine and coarse particles) - can improve particle packing before melting. Finer particles fill the gaps between larger ones, helping to create a denser, more continuous film. But if the distribution includes too many fines, it can increase melt viscosity and hinder flow, reducing leveling performance.

A well-optimized PSD balances these factors, allowing the coating to flow evenly and self-level before curing. This results in a smoother surface with fewer visual defects—especially important in applications requiring high-gloss finishes.

How Powder Manufacturers Control Particle Morphology

While manufacturers don't optimize particle packing to a theoretical extreme, they do manage PSD within a defined range that suits the coating’s end use. This balance ensures reliable performance without overcomplicating production or introducing unnecessary cost. Achieving this ideal morphology is a carefully engineered process involving several stages outlined below:

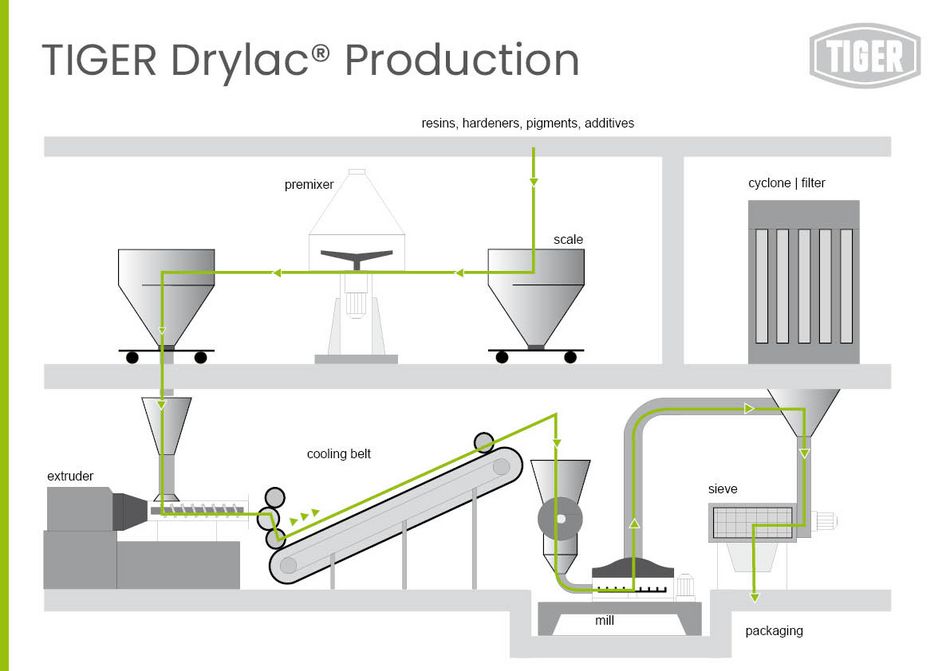

1. Resin Selection and Preprocessing

While final particle shape and size aren't typically the primary focus during formulation, the selection of resins and additives can indirectly influence how the material behaves during grinding. Powder coatings are formulated by blending resin, crosslinker, pigments, and additives. This mixture is extruded, cooled, and chipped into flakes—setting the stage for how particles will fracture during the subsequent grinding step, which ultimately affects morphology.

2. Extrusion and Cooling

Once the raw materials are melted and mixed, the extrusion process plays a key role. The cooling rate after extrusion determines how the material will fracture during grinding. Rapid cooling leads to brittle chips, which in turn break into finer particles.

3. Grinding and Micronization

The cooled chips are ground into fine particles using air classifying mills. These systems pulverize the material and separate it by size. Grinding parameters—such as rotor speed, air flow, and temperature—directly influence particle shape. Irregular shapes can result from overly aggressive grinding or poor chip quality.

4. Air Classification and Sieving

Following grinding, the powder undergoes classification through a cyclone to remove fine particles. This step is generally followed by the powder passing through a sieving mesh to remove large particles that fall outside the target size range. The result is a narrower particle size distribution (PSD), which improves flowability and ensures smooth finish during application.

5. Additives to Modify Morphology

While additives like flow modifiers are primarily used to control coating viscosity and improve surface properties during application and curing, they may also have a secondary effect on how the material behaves during grinding. For instance, certain additives can improve flow properties or reduce melt viscosity, which could indirectly influence how particles fracture. However, in most formulations, these effects on final particle shape are not a primary consideration. Instead, their main role is to enhance film leveling, reduce defects, and improve overall finish quality—especially in high-performance or appearance-critical applications.

6. Quality Control: Laser Diffraction & SEM Imaging

In production settings, particle size is typically monitored using laser diffraction. This method provides fast, consistent data on size distribution, making it suitable for daily quality control of ground powders. While it doesn’t provide information about particle shape, it helps ensure the powder falls within the desired size range for application and performance.

More advanced techniques like Scanning Electron Microscopy (SEM) are reserved for R&D situations, where detailed morphological analysis is needed.

Conclusion & Key Takeaways

Particle morphology may seem like a minor detail, but its effects ripple throughout the entire powder coating process—ultimately shaping the quality and performance of the final product.

While manufacturers may not optimize particle morphology perfectly in every batch, they maintain it within established global best-practice ranges and production tolerances. Adhering to these proven limits helps formulators achieve consistent finishes, improved efficiency, and durable end-use performance.

Back to overview