Common Powder Coating Defects & Solutions

Surface defects on a substrate can be powder coater’s worst nightmare, causing hours of rework and lost time. Some of the most common defects can come from welding, cast metals or laser cutting. Discover how to correct these issues to avoid any potential problems.

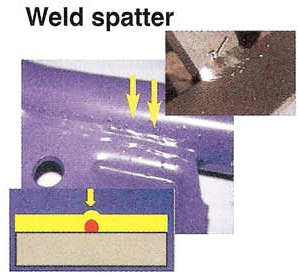

Weld Splatter

A common occurrence in welding is the creation of droplets of molten material that are generated at (or near) the welding arc called “spatter”. Spatter will cause a blemish under any perfect finish. Save time and money by grinding spatter before powder coating.

Cause:

Weld spatter from welding part

Solution:

Strip coating, grind spatter with clean tool carriage

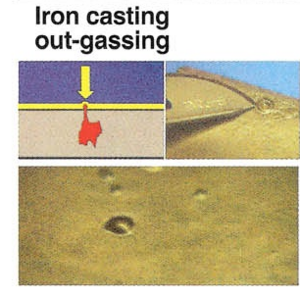

Outgassing

Outgassing is common issue when handling material such as cast metals (iron, steel, aluminum, etc.) Gasses are trapped into the casting material during the casting process. This also holds true with galvanized substrates, like Zinc Coated, especially when they are hot dipped. To help release gasses trapped in metal, preheat the substrate above cure temperature then use OGF Primer by TIGER Drylac for a flawless finish.

Cause:

Air and or gas trapped inside the casting, expanding during the heating process

Solution:

Out gas the part at a higher temperature than cure cycle of powder

Laser Cutting

Laser cut parts tend to have carbon deposits on the edges. This is created by exposure of molten steel to oxygen on the cut edge. Unremoved oxidization is highly susceptible to adhesion failure. A good way to confirm a solid coating is to remove these scales in a mechanical method such as grinding, sanding or abrasive blasting.

Cause:

Laser scale during cutting process

Solution:

Remove scale by grinding or sanding the surface

It is clear powder coaters can face many different implications regarding surface defects but use these solutions to avoid or correct some of the most common. We hope you found this content useful – please leave comments below with any questions or feedback.

Thank you, TIGER Drylac Technical Team

Back to overview