How to Choose the Correct Primer for Powder Coating Applications

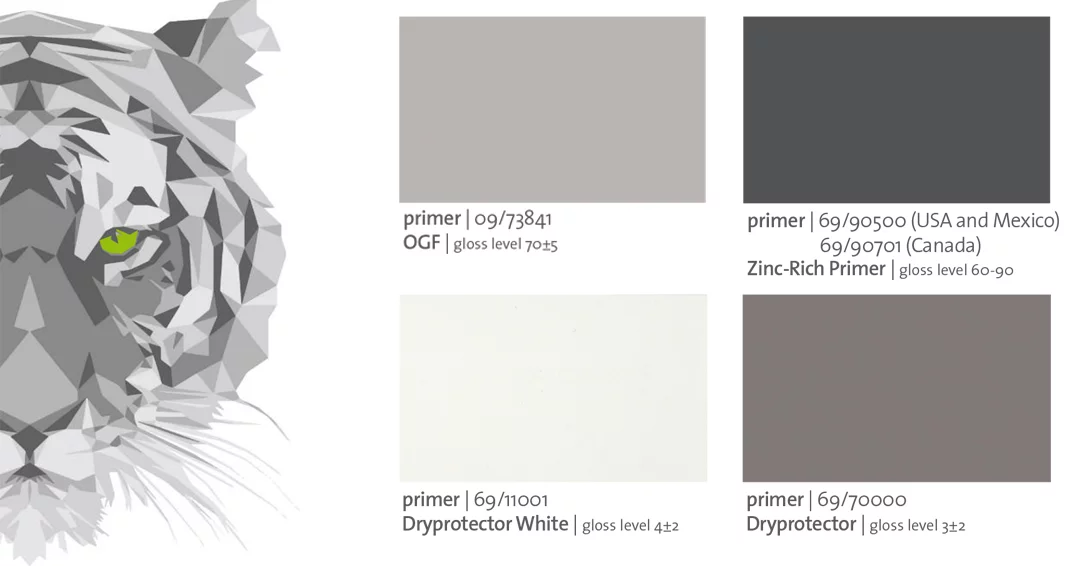

With the multitude of metal substrates that can be powder coated one question that commonly arises is, "What is the correct primer to use for my project?” A primer is typically used as the base coat in a two-coat system, which will form the protective layer over the substrate. Many primers are specifically engineered for different types of substrates or treated metals indicating that specific types will work better for certain applications. This blog will highlight three of the most common primers (Zinc Rich, Zinc Free and Outgas Forgiving) and their applications.

Zinc Rich Primers are best used for steel substrates and work exceptionally well on sandblasted steel providing inter-coat adhesion to the steel. They are NOT recommended for use on aluminum. Being enriched with zinc protects the steel against oxidation/rusting. The reasoning behind this is the zinc in the primer will sacrifice itself by combining with oxygen and moisture forming a zinc oxide layer keeping the steel protected from rust.

Zinc Free Primers/Dryprotectors are widely used in conjunction with aluminum substrates but can also be used with steel. The lack of zinc makes these powders environmentally friendly and enhances adhesion to aluminum. These are highly sought after features in the architectural industry that work primarily with aluminum. If there is no zinc in the formulation, the specific gravity of the powder will be lower resulting in better first past transfer efficiency. Pure epoxy zinc-free primers will provide superior chemical resistance compared to other primers, which is useful where a project requires resistance to cleaning agents and harsh environments. Job Shops appreciate zinc free primers because they are so versatile and can be used on a wide variety of projects. At TIGER, we have two stock Dryprotectors in a light matte finish ready to work for you.

Outgas Forgiving/OGF Primers are also considered a universal primer working with aluminum and steel. The primary benefit of these primers is achieved when coating over galvanized and cast metals. These metals trap pockets of air, gasses and other contaminants within the metal during the casting process and are released when the metal is heated. Primers with OGF properties help the trapped impurities release through the coatings, then smooth over for a clean finish. Other primers will not allow the escape of gasses and could result in bubbles and pinholes in the topcoat. For anyone who plans to coat cast or galvanized metals be sure to use a primer base coat formulated with OGF properties.

For additional information regarding primers and their use for specific powder coating applications, contact your TIGER Representative.

Phone: +1 800-243-8148

Fax: +1 877-926-8148

Back to overview