Mechanical and Chemical Pretreatment Process for Powder Coatings

Before powder coating application, a substrate needs to be properly pretreated. Cutting corners in pretreatment can lead to downstream production disasters such as peeling, corrosion and scrap. A fully cleaned part is one that is ready to accept a paint finish. Any foreign substance found between the powder coating and the substrate can interfere with adhesion. The two main pretreatment processes are:

- Mechanical pretreatment is the use of abrasive media to clean the surface.

- Chemical pretreatment is the use of chemicals to clean the surface.

Mechanical pretreatment is the use of abrasive media, which indicates rubbing and grinding, to polish or clean a surface.

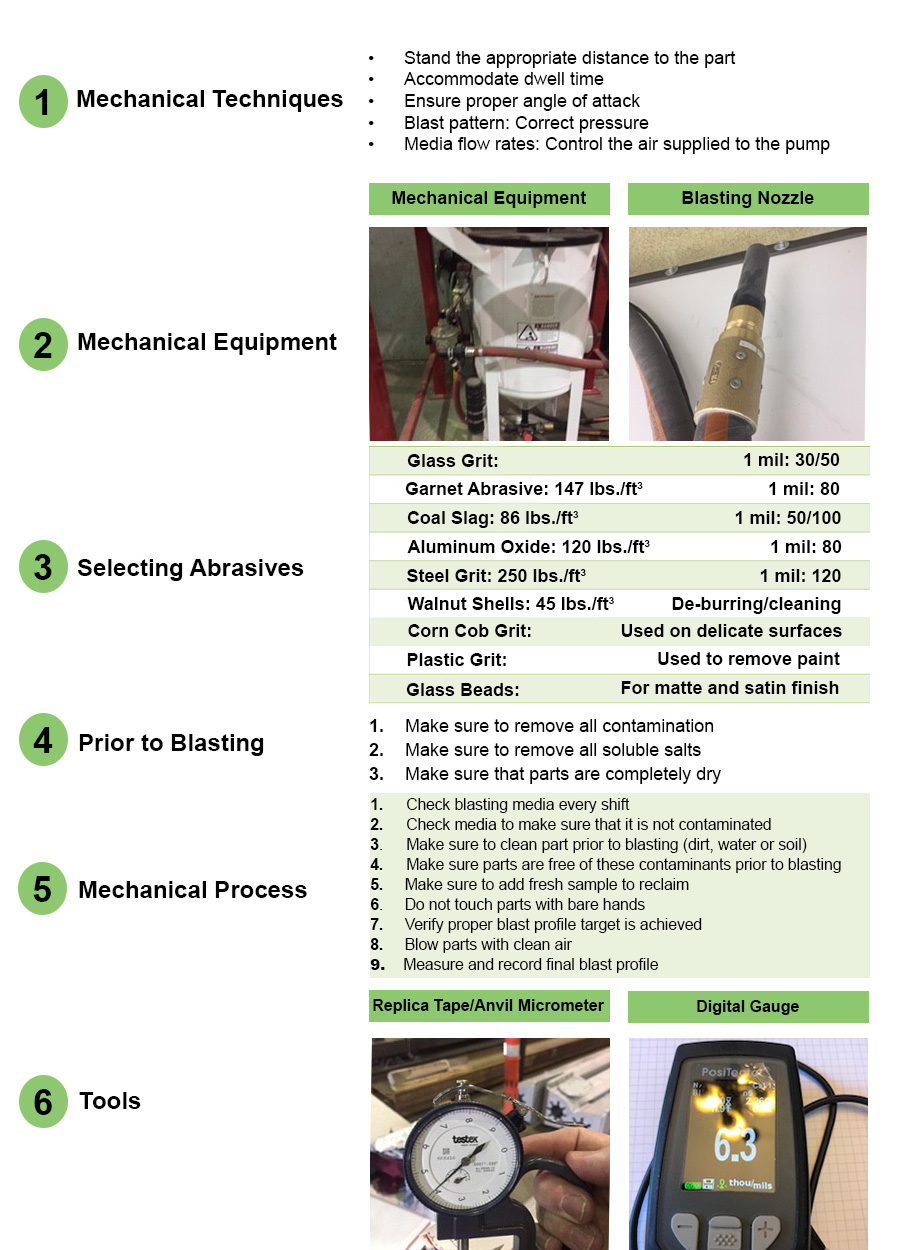

Mechanical Pretreatment Process:

Second is the use of chemicals to clean the surface, which promotes adhesion of the powder coating to adhere on slick or difficult metals.

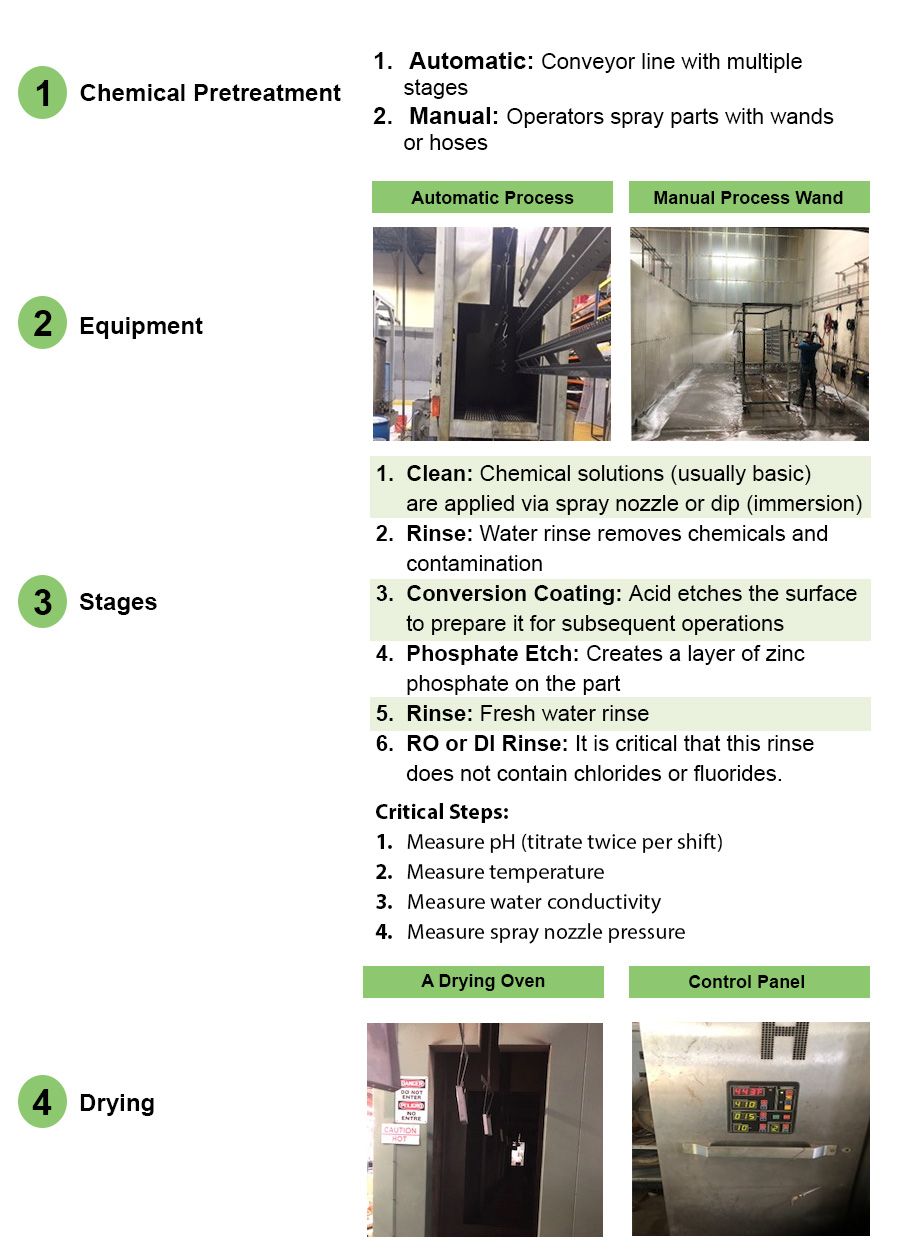

Chemical Pretreatment Process:

Lab chemists can design a powder coating with bright colors, fancy sparkles and outstanding corrosion protection. However, that powder will not stick to the part without a robust pretreatment process. Your final paint finish depends on upstream mechanical and chemical pretreatment. So please take time to remove contamination from your parts before you apply a powder coating. Remember: a clean part is a happy part!

Article by Verney Dennerville, Application Field Specialist - North America & Dan Bloden, PMT Automotive and ACE - North America

Back to overview