Corrosion Protective Coatings 101: What Are They and Why They Are Important?

Corrosion is a sneaky enemy that quietly eats away at materials through chemical or electrochemical reactions with the environment. It's like a slow but persistent force of nature, degrading material integrity over time.

Now, you might be thinking, "So what? What's the big deal with a little corrosion?" Well, it's a bigger deal than you might imagine. Corrosion doesn't just weaken and damage materials; it also takes a financial toll.

But fear not! There's a hero in the battle against corrosion, and it comes in the form of powder coating primers. These coatings work wonders in protecting materials from the clutches of corrosion. It's like a shield, sacrificing itself to shield the material surface from the relentless attacks of corrosive elements.

Introduction To Corrosion

Corrosion basically means the deterioration of a substance resulting from chemical or electrochemical reactions with its surroundings and is primarily observed in metallic surfaces.

The impact of corrosion extends beyond compromising the strength and longevity of materials; it also presents a costly predicament for you and the environment. Equipment damage and product leakage, particularly in the chemical industry, pose significant threats to the environment.

Factors That Lead to Corrosion

High humidity, temperatures above freezing, and reactive air contaminants (such as sea salt) are the big drivers of metal corrosion. In addition, aggressive chemicals can trigger, favor, and accelerate this process. If no countermeasures are taken, a steel surface can degrade up to 0.2 mm of layer thickness in just 1 year!

Corrosion Protection with Powder Coating Primers

Where there is metal, there is potential for rust! If such damage is not detected in time, it can lead to material failure. In industrialized countries, the annual loss due to corrosion can amount to about three to four percent of the gross domestic product. Based on the G20 countries, the global economy lost between 2.4 to $3.15 trillion USD to corrosion in 2021 alone.

What Are Corrosion Protective Coatings?

Corrosion Protection Coatings are a special type of coating applied to metal surfaces to shield the underlying surface from potential corrosive damages by water, oxygen, or electrolytes. The utilization of corrosion protection coatings offers a means to enhance the performance and lifespan of metals and other substrates.

Anti-corrosion coatings function as sacrificial materials, creating a protective "barrier layer" on the surface of the material to combat corrosion. They can be created using substances like zinc and usually applied as a base layer, or primer.

Advantages Of Corrosion Protective Primers and Coatings

The advantages associated with employing corrosion-resistant coatings are as follows:

- Heightened efficiency of metals and other components

- Material surfaces with improved functional characteristics and properties

- Streamlining industrial operations

- Acts as a protective layer against damages from oxidation, moisture, exposure to harmful chemicals, etc.

- Reduction in maintenance and replacement expenses

- Conservation of natural resources

- Mitigation of polluting emissions

How Do Corrosion Protective Coatings Work?

Corrosion protection coatings and primers, when carefully applied to properly cleaned metal surfaces, form a protective layer that facilitates optimal structural bonding. Additionally, due to their excellent corrosion resistance properties, these coatings effectively safeguard material surfaces from the detrimental effects of further oxidation.

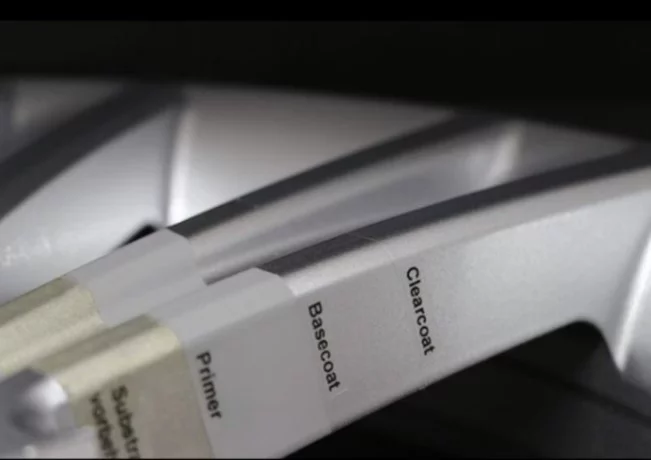

When it comes to multi-layered coating practices in relation to preventing corrosion, there are two important layers: the primer and the topcoat. If the primer doesn't adhere well to the substrate or doesn't work well with the topcoat, there's a chance it will fail early. This can be caused by more than one factor including topcoat not curing properly or excessive thickness of primer.

It’s important to note that the primer makes the metal substrate highly active and ideal for further layers to be easily added. But it also provides cathodic protection, an electrochemical phenomenon used for protecting metal surfaces from rust.

To learn more about corrosion protection, then check out our article about effective corrosion protection with powder coating and primers.

Use TIGER’s Corrosion Protection Primers to Prevent Corrosion

High-quality pretreatment in combination with powder coating offers good protection against weathering. However, one coat of powder is often not enough, especially for steel applications. For example, on sharp edges there is only a small amount of powder coating after treatment when compared to the remaining surface. This in turn impairs the corrosion protection of the entire surface. For these applications, TIGER Drylac offers powder coating primers applied to the substrate before the topcoat. The special formulation of the primers and the additional coating thickness provide optimum protection against corrosion for a wide range of equipment, machinery and plants.

TIGER Shield 2-Coat System

Primers are available in different colors and qualities for steel, galvanized steel and aluminum. The 2-layer TIGER SHIELD system consists of powder coating primer as well as a topcoat and is suitable for applications requiring the highest corrosion resistance.

Zinc Rich Primers

TIGER Drylac 69/90500

Zinc-Rich epoxy-based Primer for protection of steel substrates in a two-coat TIGER Shield system.

- Primer for steel substrates

- Very good corrosion protection

- Very good mechanical properties

- Very good edge coverage

- Good inter-coat adhesion

- Good chemical resistance

- Good storage stability

Zinc-Free Primers (Dryprotector)

TIGER Drylac 69/70000

Epoxy Zinc-Free Primer to be used on aluminum and steel substrates as part of a two-coat TIGER

Shield system.

- Very good corrosion protection

- Very good edge coverage

- Good inter-coat adhesion

- Good chemical resistance

- Good storage stability

- Good mechanical properties

Outgas Forgiving (OGF) Primers

TIGER Drylac 09/73841

Epoxy-polyester based primer with excellent flow for corrosion protection in application over castings.

- Outgassing friendly

- Excellent flow

- Especially suitable for overcoating with wet paint

Primers provide benefits in addition to corrosion protection, like improved adhesion and can assist in providing a smoother surface for the topcoat, but corrosion protection is paramount to corrosion resistance for a quality powder coating application, so make sure to use the correct Primer for the job! Visit our Webshop to find the best corrosion protection coatings and primers for your needs.

Back to overview