Two-Coat Powder Coating Application Process

The two-coat process involves two coatings applied to the same substrate. The purpose of this method is to enhance the appearance of the finish while protecting it from natural elements. In powder coating, there are a variety of applications that require a two-coat process, which can be intimidating projects for novices or even challenging for veterans. Follow these simple rules and tips to get the best results for your specific type of project:

Partial curing is the best method while doing multiple coats. This powder coating process will properly crosslink and bond the two coats. The best inter-coat adhesion is achieved when pre-gelling the base coat at 392°F (200°C) for 2-3 minutes before applying the second layer. The topcoat is then cured for a full cycle in conformity to the applicable Product Data Sheet (PDS) of the powder coating system used.

Simply put, first you want the base coat to gel, flash, glaze, or look sticky. Secondly, remove the substrate from the oven and let cool to 175 to 200°F (79 °C - 93°C). Finally, apply the topcoat and put the substrate back in the oven for a full cure cycle.

Most common two-coat processes that use partial curing methods:

1. The use of a primer with a topcoat. To help protect substrates from oxidizing and give additional corrosion protection.

2. The use of a clear coat on top of a basecoat. To modify the look of the finish – glossy, matte, texture, etc.

Partial Curing Parameters:

Substrate Temperature | Min. Curing Time | Max. Curing Time |

338 °F (170 °C) | 5 Minutes | 10 Minutes |

392 °F (200 °C) | 2.5 Minutes | 5 Minutes |

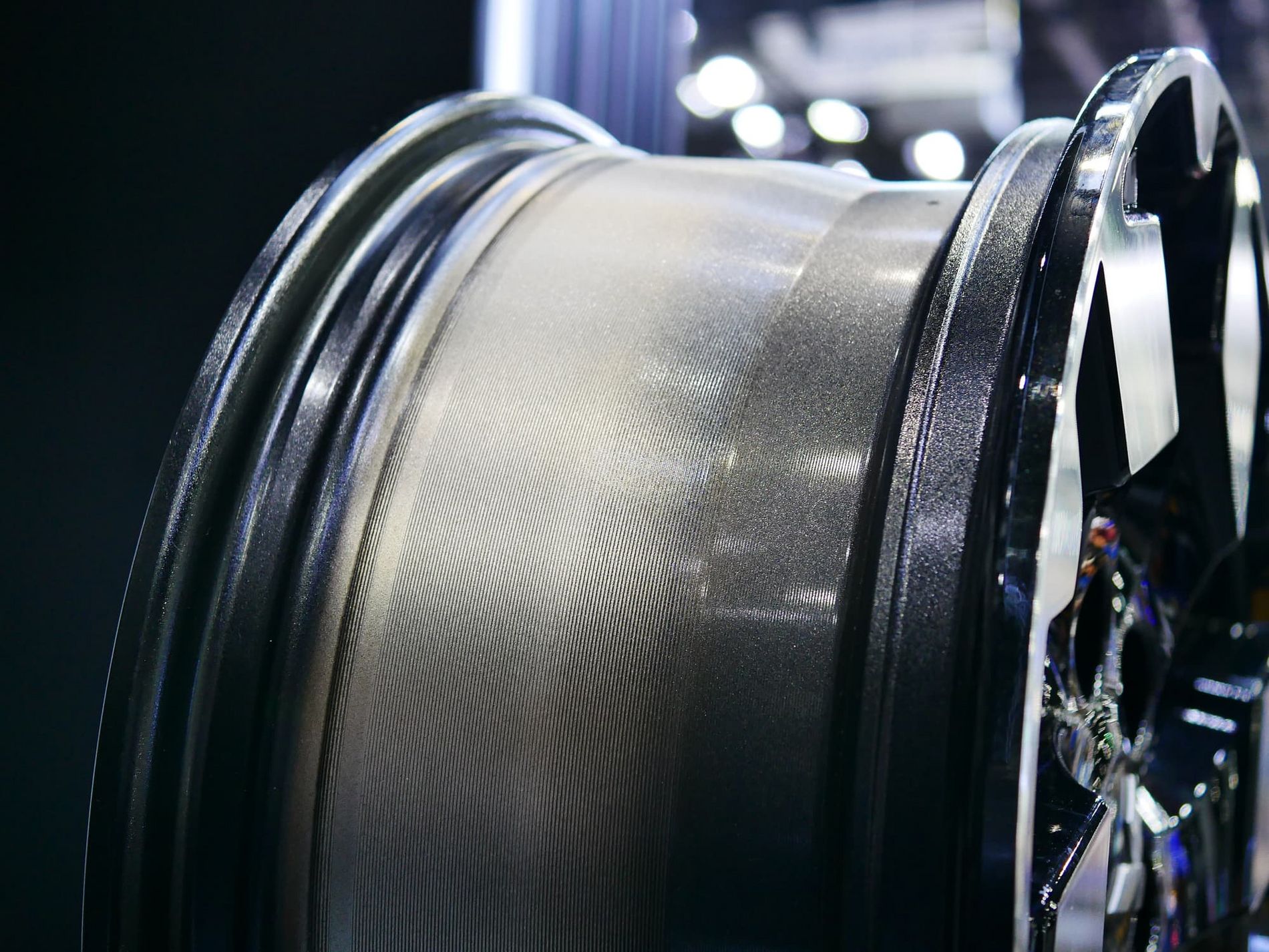

Specialty two-coat processes: Candies, Chrome, and Metallics

1. The use of brilliant reflective surface powder coatings such as Candies and Chromes are required to be cured at 100% or at least 75% of the curing parameters.

2. The use of metallic powder coatings as a base, cure time between 50-75% of the curing parameters as described in the applicable Product Data Sheet. This method will reduce variations in the metallic effect.

Specialty Curing Parameters:

Substrate Temperature | Min. Curing Time | Max. Curing Time |

338 °F (170 °C) | 10 Minutes | 15 Minutes |

392 °F (200 °C) | 7.5 Minutes | 10 Minutes |

To avoid contamination, a maximum of 12 hours must elapse between the application of the base coat and the topcoat. For metallic finishes, it is recommended to observe the guidelines published in the latest Information Sheet. Please consult the manufacturer before applying any 2-coat systems that feature (i) a primer or e-coat as a base coat and (ii) a metallic effect powder coating as a topcoat.

It is also important to note that top coating with a clear exterior grade powder coating over an interior grade powder coating does not result in a weather resistant coating system. For the best results, proper pretreatment is necessary. Therefore, a suitability test at the applicator’s end, before coating, is highly recommended. Please read and understand the technical information to ensure the best results for two-coat applications.

Happy coating!

Back to overview