What are TIGER 2nd Generation Bonded Metallics?

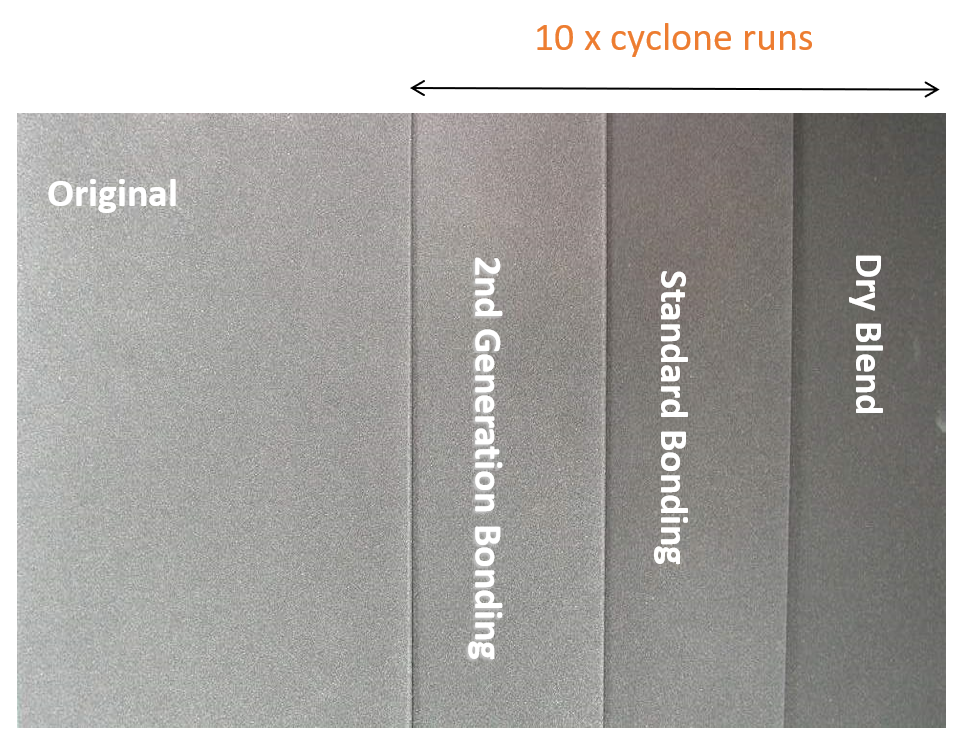

TIGER Drylac Metallics are made with our 2nd Generation Bonding technology, which is exclusive to TIGER Drylac® Metallics. This State-of-the-art system bonding of metallic pigments to the base material offers unique advantages over conventional dry blending. This process features:

- An even distribution of pigments for a more uniform metallic finish

- Unparalleled Batch-to-batch consistency

- Low effect variation at different applications

- Resistance to particle segregation during transportation and storage

- Low reject rates & fewer application issues

- Easy to spray powder

- Less separation of Powder and Pigment during application (fewer charging issues)

- Higher Transfer Efficiency

- A recycling consistent material, making the powder suitable for reclaim

TIGER Metallic Powder Coatings

- The metallic is bonded to the surface of the powder particle

- This process helps to place some metallic particles parallel to the substrate but there are also particles not parallel or even perpendicular to the substrate

- This creates a distinct difference in appearance from liquid that is difficult to recreate in ordinary powder coatings

Liquid Metallics

- For the most part, the binders in liquid systems are lower molecular weight; smaller molecules and lower viscosities

- The liquid system’s low viscosity and the solvent evaporation process will orient the metallic; push it to the surface parallel to the substrate (it lies flat)

- If metallic’s are not involved, liquid coating are easy to make smooth but hard to build film and create certain textures

Back to overview